Proven Methods to Lower Waste Production in Factories

The industrial sector has always been a crucial element of the global economy, but it also plays a substantial role in environmental pollution due to waste production. Implementing effective strategies to reduce waste is essential for factories aiming for sustainability. In this article, we explore several proven methods to minimize waste generation in factories that not only benefit the environment but also enhance operational efficiency.

Understanding the Importance of Waste Reduction

Before delving into the methods, it's vital to understand why reducing waste in factories is crucial. Excessive waste can harm the environment, contribute to climate change, and lead to significant financial losses for companies. Therefore, adopting waste reduction strategies can result in a win-win situation, helping to meet both environmental and economic goals.

Strategies for Reducing Waste in Industrial Settings

1. Conducting a Waste Audit

A comprehensive waste audit is the first step towards reducing waste. This involves identifying the types and quantities of waste produced, which areas are most production-heavy, and potential sources of inefficiency. Conducting a waste audit helps in pinpointing key areas of improvement, making it an essential part of any waste reduction strategy.

2. Embracing Lean Manufacturing

Lean manufacturing is a systematic method for waste minimization without sacrificing productivity. It focuses on optimizing production processes and maximizing value by eliminating waste. Companies practicing lean manufacturing:

- Enhance production efficiency.

- Reduce material wastage through precise inventory management.

- Utilize continuous improvements to avoid waste creation.

It is a cornerstone strategy ensuring that the least amount of waste is generated during production.

3. Implementing the 5S Methodology

The 5S methodology is a workplace organization method that enhances efficiency and reduces waste through five phases - Sort, Set in order, Shine, Standardize, and Sustain. This approach streamlines operations, improves safety, and leads to a cleaner production environment.

4. Adopting Eco-friendly Technologies

Investing in eco-friendly technologies can significantly lower waste production in factories. New advancements such as energy-efficient machines, recycling systems, and biodegradable materials can minimize the environmental impact. By adopting such technologies, industries can:

- Lower energy consumption.

- Reduce raw material waste.

- Enhance recycling processes.

These technologies not only reduce waste but also contribute to a factory's sustainability goals.

5. Training and Engaging Employees

Employees play a crucial role in the implementation of waste reduction methods. Training programs that focus on waste management practices and eco-friendly procedures foster an environment where all staff members are engaged in waste reduction efforts. Encouraging employees to offer suggestions for improvement can also result in innovative waste reduction solutions.

Recycling and Reusing Materials

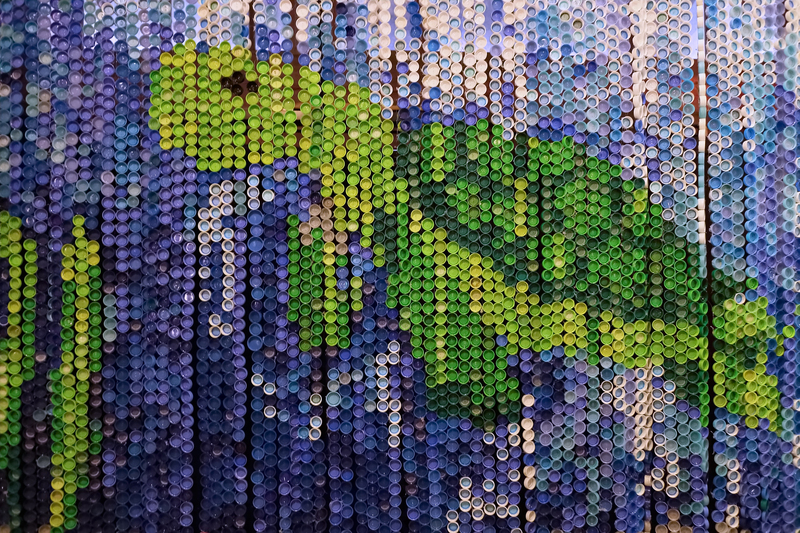

Recycling and reusing materials is a practical approach to minimizing waste in factories. By finding ways to reuse scrap and excess materials, factories can divert significant quantities of waste from landfills. For instance:

- Repurposing product offcuts into new products.

- Implementing a closed-loop recycling system.

- Donating excess or by-products for use in other industries.

This practice not only lowers waste but also reduces costs associated with purchasing new materials.

Leveraging Data and Automation

Advanced technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) offer powerful tools for waste reduction. By utilizing data analytics and automation, factories can monitor waste production in real-time, forecast future waste, and make informed decisions to reduce waste further:

- Automate production lines for precision.

- Use predictive maintenance to prevent machinery breakdown and wastage.

- Analyze production data for continuous improvement and waste minimization.

Partnering with Sustainable Suppliers

Collaboration with suppliers committed to sustainability can help in reducing waste associated with material sourcing and transport. Prioritizing suppliers who use eco-friendly packaging and sustainable materials can minimize your factory's overall waste footprint. Sustainable partnerships lead to a more responsible supply chain.

Final Thoughts on Reducing Waste in Industrial Environments

In conclusion, reducing waste production in factories is not only an environmental necessity but also a strategic business decision that enhances efficiency and reduces costs. By implementing these proven methods, factories can significantly minimize their environmental impact, comply with regulations, and achieve long-term sustainability. The key lies in awareness, innovation, and a steadfast commitment to continuous improvement.

Lowering waste in factories is a journey that demands commitment and collaboration across all levels of the organization. With the right strategies and technologies, industries can move towards a more sustainable future while also improving their bottom line.